By Joseph White and Paul Lienert

DETROIT (Reuters) – General Motors Chief Executive Mary Barra is betting that moving more slowly than Tesla or Ford to accelerate electric vehicle production for North America will be more profitable in the long run.

Suppliers familiar with GM’s production plans through 2025 support the notion the automaker continues to slow-walk electric vehicle investment and output while it continues to bank money from its big combustion-engine pickups and SUVs.

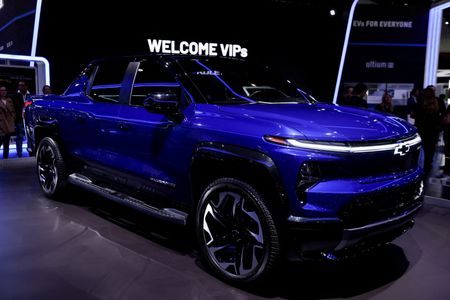

GM plans to build just 170,000 EVs at its plants in the U.S., Canada and Mexico in 2023, and 285,000 in 2024, according to data gathered by AutoForecast Solutions, which expects the automaker’s EV production to remain under 500,000 in 2025 – about half of its actual capacity of 1 million.

“GM knows it needs to look like a tech company to Wall Street and prop up its stock price by talking about its EV future … but its bread and butter remains large pickups and SUVs with V8 engines, which continue to generate most of the company’s profits,” said Sam Fiorani, vice president of global vehicle forecasting at AutoForecast Solutions.

GM is launching four new EVs this year – one pickup and three SUVs – and four more in 2024, but most will be built in relatively low volumes through 2025, according to AFS.

GM on Tuesday stuck to its plan to produce a total of 400,000 electric vehicles for North America from 2022 through the first half of 2024. Most of those 400,000 vehicles will be built starting later this year, Barra and GM Chief Financial Officer Paul Jacobson said in conference calls.

GM said it has secured all the battery materials it will need to build 1 million EVs a year in North America by 2025. Tesla this week said it is investing $3.6 billion to expand its Nevada battery plant to support 2 million vehicles of annual production.

BATTERY PLANTS

GM is building three U.S. battery plants with partner LG Energy Solution, and Barra said the automaker will need more. But she declined to say when GM will move forward with plans for a fourth U.S. battery factory.

By contrast, Ford announced plans Monday to cut prices for its Mustang Mach-E electric SUV by as much as 8%, and reaffirmed a goal of selling 600,000 EVs annually by the end of 2023. Ford had previously set a target to increase North American production for the Mach-E to 130,000 vehicles this year.

By this fall, Ford plans to expand production capacity for its F-150 Lightning electric pickup to 150,000 vehicles a year.

In the short run, GM’s go-slow approach could allow it to side-step the price war that Tesla launched earlier this month. Investors appeared to be on board Tuesday with GM’s approach and its bullish financial forecasts, sending shares up more than 7%.

Barra said orders are strong for GM’s new EVs, such as the GMC Hummer pickup and SUV, the Cadillac Lyriq and the electric Chevrolet Silverado pickup.

“Right now based on the interest” in those models, “the pricing we put out was very appropriate,” Barra told analysts during a call.

Overall, Barra and Jacobson said, GM will work to avoid discounting by holding inventories of all vehicles – combustion powered and electric – much tighter this year than in the pre-pandemic past. GM wants to end this year with 50 to 60 days worth of vehicles at U.S. dealers, 20 to 30 days less than was normal in 2019, Jacobson said.

Production of GM’s newest EVs is ramping up slowly. GM delivered just 122 Cadillac Lyriq SUVs and 854 Hummer pickups last year.

Production of the electric Hummer SUV began this week, GMC brand chief Duncan Aldred said Monday. The division has 90,000 reservations for the high-performance Hummer EVs and is sold out into next year, he said.

(Reporting By Joe White and Paul Lienert; Editing by Nick Zieminski)